The manufacturing industry has always been at the forefront of technological advancements. From the Industrial Revolution to the automation of production lines, the sector has constantly evolved. Today, we stand at the precipice of another transformative shift: the integration of human-machine collaboration. As machines become more intelligent and capable, and as humans continue to bring their creativity and problem-solving skills to the table, the future of manufacturing is set to be defined by a new era of collaboration.

In this blog, we will explore the exciting prospects of the future of human-machine collaboration in manufacturing and discuss how this synergy can drive innovation, increase efficiency, and usher in a new era of productivity.

The Rise of Automation and Robotics

Automation and robotics have already revolutionized manufacturing, leading to increased precision, consistency, and productivity. However, the future of manufacturing will see even more seamless integration of automation and robotics into production processes.1. Collaborative Robots (Cobots): Cobots are designed to work alongside human operators, facilitating tasks that require a delicate touch or a high degree of flexibility. They can assist with everything from assembly to quality control, making production lines more efficient and adaptable.

2. AI-Powered Machines: Machines enhanced with artificial intelligence (AI) are becoming increasingly capable of performing complex tasks. These machines can adapt to changing conditions, make real-time decisions, and even predict maintenance needs, reducing downtime and optimizing production schedules.3. 3D Printing: Additive manufacturing, or 3D printing, is another area where humans and machines collaborate. Humans design the products, while machines bring these designs to life with incredible precision. This technology not only accelerates prototyping but also enables the creation of highly customized, intricate parts.

Enhancing Safety and Quality Control

Human-machine collaboration in manufacturing isn’t just about efficiency; it’s also about ensuring safety and maintaining quality standards.1. AI-Powered Inspection: AI-driven quality control systems can identify defects and anomalies with unparalleled accuracy. Human operators work alongside these systems to fine-tune them, ensuring that they learn from new data and continuously improve their performance.

2. Predictive Maintenance: Predictive maintenance systems, driven by machine learning algorithms, can predict when machines are likely to fail. Human maintenance teams can then step in to perform the necessary repairs, preventing costly breakdowns and production delays.The Role of Humans in Manufacturing

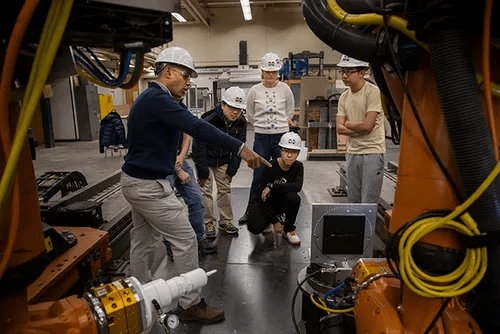

While automation and AI are transforming manufacturing, they will not replace humans. Instead, they will augment human capabilities, allowing workers to focus on tasks that require creativity, problem-solving, and decision-making. Here are some ways humans will continue to play a vital role:

1. Design and Innovation: Humans will remain at the forefront of design and innovation. They will conceive new products, optimize production processes, and constantly seek ways to improve efficiency.2. Complex Decision-Making: Complex decision-making, especially in situations that involve ethical, strategic, or unforeseen factors, will remain a human domain. Machines can provide data-driven insights, but humans will have the final say.

3. Maintenance and Repair: Even with predictive maintenance systems in place, humans will still be needed for hands-on maintenance and repair work. Their expertise and adaptability are invaluable when dealing with unexpected issues.

The future of human-machine collaboration in manufacturing is undoubtedly promising, but it also comes with challenges and considerations:

1. Workforce Reskilling: As manufacturing becomes more technologically advanced, there will be a need to reskill the workforce to operate, program, and troubleshoot the new technologies effectively.

2. Data Security: The increased use of data-driven systems requires robust cybersecurity measures to protect sensitive information from cyber threats and breaches.3. Ethical and Social Impact: The ethical implications of automation and job displacement must be carefully considered, and strategies for a just transition to the future of work should be developed.

Conclusion

The future of manufacturing lies in the synergy between humans and machines. As automation, AI, and robotics continue to advance, they will enhance productivity, safety, and quality in the industry. However, the role of humans in manufacturing is far from obsolete; it is evolving. Humans will remain the driving force behind innovation, creativity, and complex decision-making. The key to success in this new era of manufacturing is collaboration—where humans and machines complement each other’s strengths to create a more efficient and innovative industry. Embracing this collaboration will not only benefit manufacturers but also pave the way for a more sustainable and technologically advanced future.

You must be logged in to post a comment.