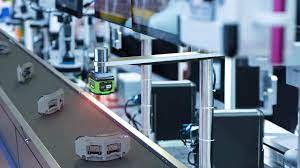

Manufacturing has seen a dramatic transformation over the years, driven by advances in technology. Among these advancements, the integration of vision-guided robots into manufacturing processes has revolutionized the industry. These robots, equipped with sophisticated vision systems, are capable of performing tasks with precision and speed, enhancing efficiency in ways previously unimaginable. In this blog, we’ll explore the role of vision-guided robots in manufacturing and how they are reshaping the landscape of industrial production.

The Power of Vision in Robotics

Robots have long been an essential part of manufacturing, performing repetitive and often dangerous tasks. However, traditional robots were limited in their capabilities. They were typically programmed to follow predefined paths or execute specific tasks, making them inflexible and unable to adapt to changing environments or tasks.

Vision-guided robots, on the other hand, are equipped with cameras and sophisticated image processing software that allows them to “see” and interpret their surroundings. This visual perception empowers them to:

- Recognize Objects: Vision systems enable robots to identify and locate objects, even in cluttered or chaotic environments. This capability is crucial in tasks that involve picking and placing items.

- Quality Control: Vision-guided robots can inspect products for defects or deviations from quality standards. They can identify imperfections that may not be visible to the human eye.

- Navigation: These robots can navigate autonomously, avoiding obstacles and adjusting their paths as needed. This is particularly useful in dynamic environments.

- Adaptability: Vision-guided robots can adapt to variations in product design or assembly, making them versatile across multiple product lines.

How Vision-Guided Robots Enhance Efficiency in Manufacturing

- Improved Precision: Vision systems enable robots to perform tasks with unparalleled precision. This is invaluable in tasks like assembling intricate components or placing small parts.

- Faster Production: Vision-guided robots can work at high speeds while maintaining accuracy. This translates to increased production rates and reduced cycle times.

- Reduced Errors: The ability to detect and correct errors in real-time minimizes costly mistakes in manufacturing processes.

- Flexibility: Manufacturers can reprogram vision-guided robots for different tasks quickly, reducing downtime during product changeovers.

- 24/7 Operation: These robots can work around the clock, increasing productivity and reducing labor costs.

Practical Applications of Vision-Guided Robots

- Automated Assembly: Robots equipped with vision systems can assemble complex products with multiple components, ensuring perfect alignment and placement.

- Pick-and-Place Operations: Vision-guided robots excel in picking items from conveyor belts, bins, or pallets and accurately placing them in desired locations.

- Quality Inspection: They can identify defects or inconsistencies in products, ensuring that only high-quality items reach the market.

- Material Handling: Vision-guided robots can safely move materials within a facility, such as transferring heavy loads or managing inventory in warehouses.

- Welding and Coating: In industries like automotive and aerospace, these robots can precisely weld or apply coatings to components.

Conclusion

Vision-guided robots have emerged as a game-changer in the manufacturing sector, enhancing efficiency, precision, and flexibility in production processes. As technology continues to advance, these robots will play an increasingly pivotal role in various industries, from automotive and electronics to food and pharmaceuticals. The future of manufacturing is undeniably intertwined with the capabilities of vision-guided robots, shaping a more efficient and innovative industrial landscape.

You must be logged in to post a comment.